In high-end manufacturing, coating quality is a critical determinant of product reliability and service life. Whether for PCB conformal coating, semiconductor encapsulation materials, automotive electronic coatings, or medical/biotechnical coatings, even minor coating defects can pose potential risks of product failure.

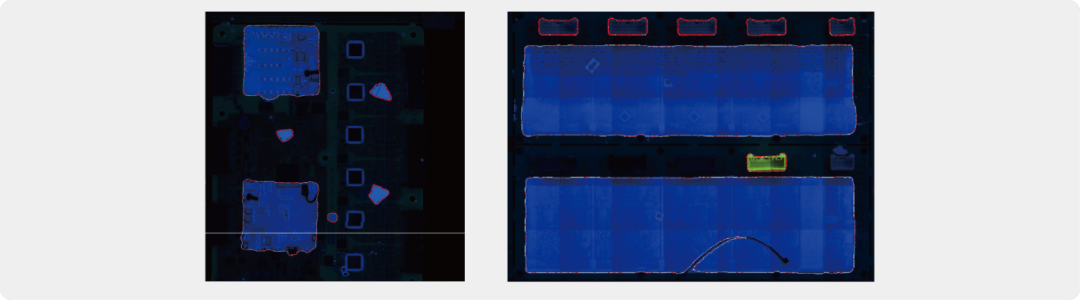

Guangdong Anda Automation Solutions Co., Ltd. has introduced the Dual-Sided On-the-Fly Imaging Coating AOI system, which integrates AI vision and on-the-fly imaging technology to deliver an efficient and accurate solution for coating inspection.

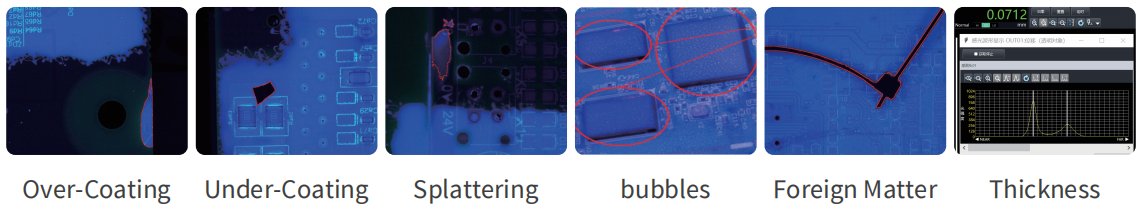

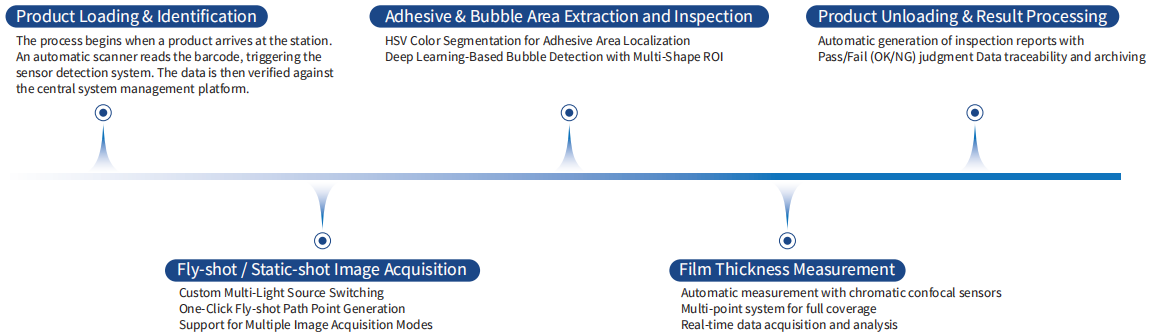

The system supports six inspection items: Over-Coating, Under-Coating, Splattering, Bubbles, Foreign Matter, and Film Thickness Measurement, enabling full-process control from visual positioning to thickness measurement.

Adopting on-the-fly imaging technology to complete image acquisition during motion, the single-field inspection time is 0.23 seconds, and the minimum detectable diameter is 0.1mm, improving inspection throughput while ensuring precision.

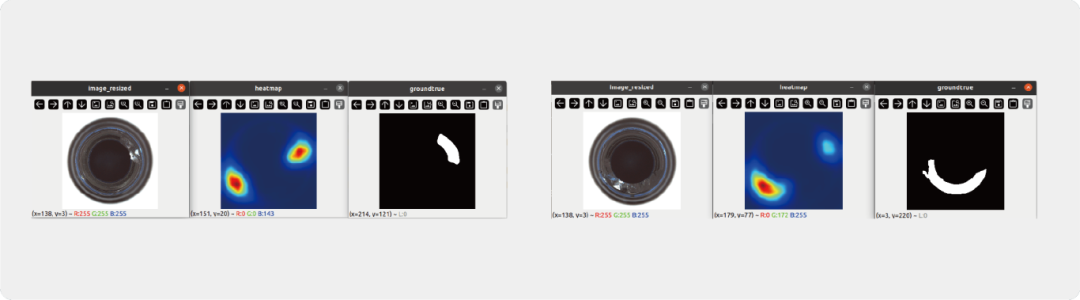

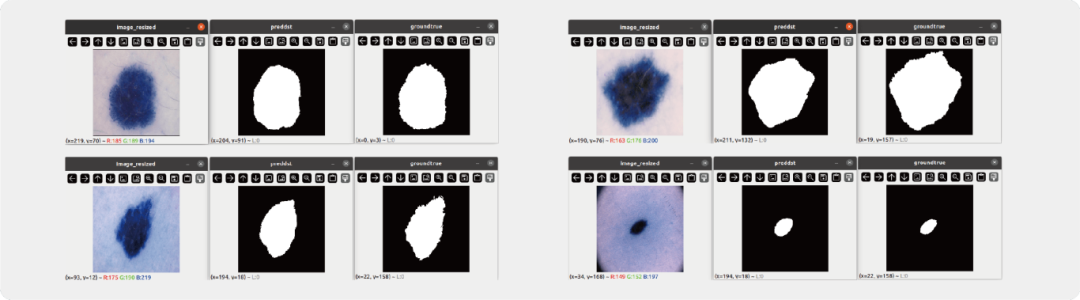

Leverages the Segment Anything Model (SAM) for coating area extraction

Zero-Shot Defect Recognition;

High-Precision Defect Identification

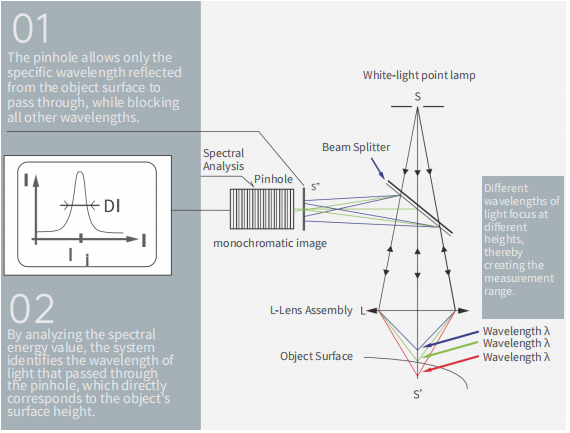

This measurement method is based on the principle of chromatic confocal sensing. A white-light point source emits a broad-spectrum beam. A lens group then creates axial chromatic aberration, meaning different wavelengths focus at different points along the optical axis. When the light irradiates the film surface, only the specific wavelength that satisfies the confocal condition is reflected back and passes through the pinhole. A spectrometer analyzes this wavelength to precisely determine the corresponding film thickness or surface height.

The system supports full-process automation from product scanning and image capture to result output, enabling rapid changeover to meet the needs of multi-variant production.

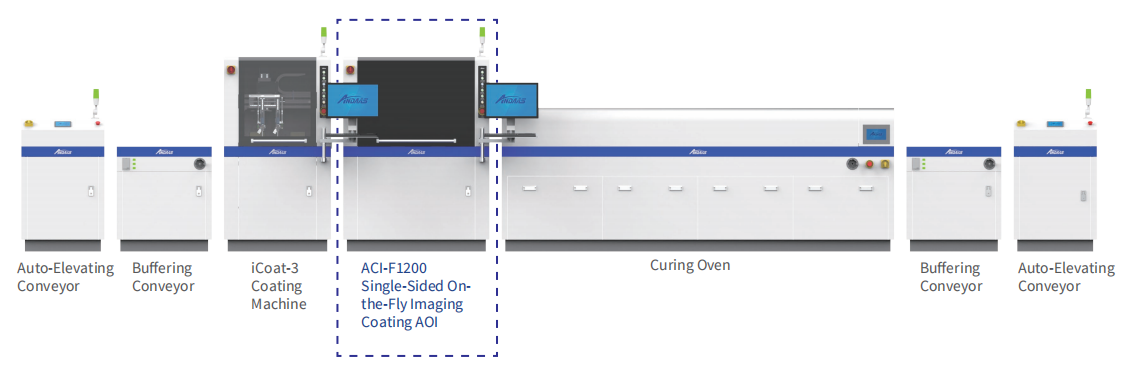

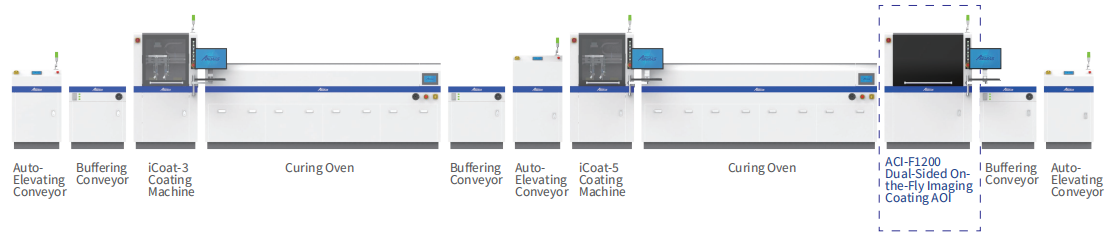

The system can be flexibly configured to support two typical production line layouts:

Single Machine & Single Oven:

Including Auto-Elevating Conveyor, Buffering Conveyor, iCoat-3 Coating Machine, ACI-F1200/500 Single-Sided On-the-Fly Imaging Coating AOI, Curing Oven and other equipment, realizing full-process automation of coating, inspection and curing.

Dual Machines & Dual Ovens:

Supports manual board loading/unloading. The production line configuration includes two coating machines (iCoat-3 and iCoat-5), two curing ovens, Dual-Sided On-the-Fly Imaging Coating AOI, and multiple buffering and elevating equipment, suitable for high-efficiency and complex processes of dual-sided coating.

Both solutions have quick changeover capabilities to adapt to multi-variety and small-batch production needs, and can conduct data interaction with MES systems to achieve quality traceability and process control.

Anda is committed to promoting the intelligent development of the manufacturing industry through technological innovation. Integrating machine vision, motion control and AI algorithms, the system provides reliable quality assurance for precision coating processes.

电话

手机

微信

公众号

抖音